Mastering the art of diaphragm wall construction is an essential skill in civil engineering, especially when tackling complex projects. This technique, celebrated for its stability and versatility, is frequently employed in excavation tasks for deep foundations, underground structures, and retaining walls. In this article, we’ll delve into the various methods, benefits, and best practices associated with diaphragm wall construction in India.

Techniques and Advantages of Diaphragm Wall Construction

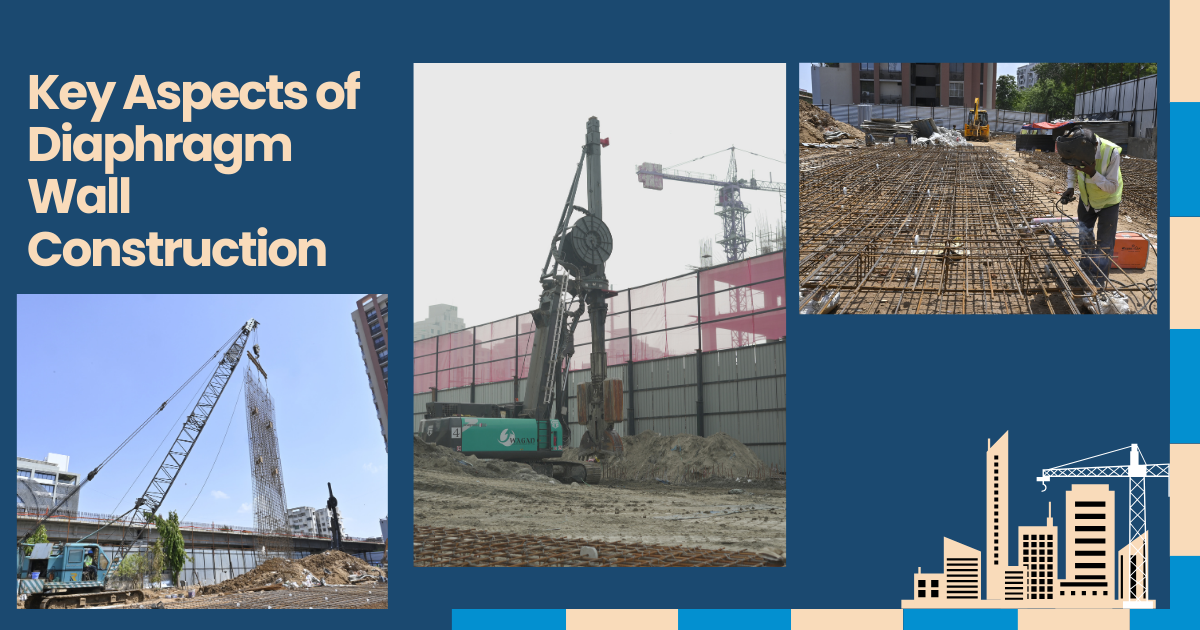

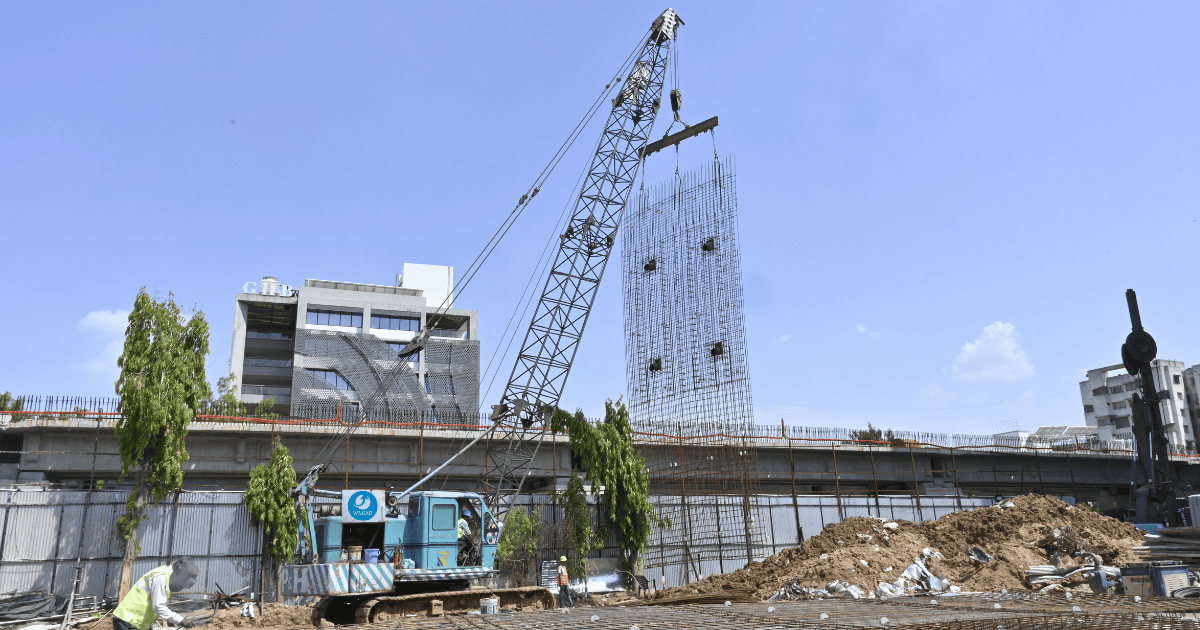

Diaphragm wall construction involves digging a trench and placing a series of interlocking concrete panels. This approach is becoming increasingly popular in India due to its effectiveness in various building projects. These panels act as both the retaining structure and the formwork for the wall. The method offers numerous benefits, including a high load-bearing capacity, a smaller excavation footprint, and the ability to withstand substantial water pressure.

To excel in Diaphragm wall construction in India, engineers need a deep understanding of design principles, construction techniques, and quality control measures. This guide will provide a thorough overview, covering essential aspects like panel installation, waterproofing methods, and concrete placement.

Whether you’re a seasoned engineer or just starting out in the field, this article will equip you with the insights needed to thrive in diaphragm wall engineering. Let’s explore the techniques, benefits, and best practices that can pave the way to success in this specialized area.

The Growing Importance of Diaphragm Walls

In the realm of construction, diaphragm walls have become crucial, especially for projects involving deep excavations, underground structures, and retaining walls. These specialized concrete walls are highly valued for their ability to provide robust support and stability in challenging soil conditions.

One key reason for the rising adoption of Diaphragm wall technology in India is their effectiveness in areas with high water tables, poor soil quality, or unstable geological formations. Diaphragm walls are designed to retain the surrounding earth and prevent soil movement or collapse, making them indispensable for deep foundations, basement levels, and other underground structures where traditional methods fall short.

Engineers design diaphragm walls to endure significant lateral loads, making them ideal for projects that require high load-bearing capacities, such as high-rise buildings, bridges, and transportation infrastructure. These walls provide the structural strength and load-bearing capabilities necessary to ensure the safety and stability of large-scale projects.

Best Practices for Diaphragm Wall Construction

For successful Diaphragm wall construction, adhering to best practices is vital. These practices, refined through extensive industry experience, include:

-

Comprehensive Site Assessment: Before starting construction, conduct a thorough site evaluation and geotechnical investigation to understand soil conditions, groundwater levels, and other factors influencing the design and build of the diaphragm wall.

-

Detailed Planning and Design: Designing a Diaphragm wall is complex and requires experienced engineers to carefully plan dimensions, reinforcement, and concrete mix to meet safety and performance standards.

-

Rigorous Quality Control: Implement strict quality control measures throughout the construction process, including regular inspections, material testing, and adherence to construction protocols.

-

Effective Waterproofing: Ensure long-term durability by using high-quality materials and proven techniques for waterproofing and sealing.

-

Ongoing Monitoring and Maintenance: After completion, maintain a monitoring plan to ensure the wall’s performance and safety, including regular inspections and necessary repairs.

-

Collaborative Communication: Effective coordination among civil engineers, construction teams, and project managers is crucial for a successful build.

By following these best practices, professionals can ensure that diaphragm wall construction India is executed efficiently, safely, and to high standards.

Addressing Challenges in Diaphragm Wall Construction

While diaphragm walls offer numerous benefits, they also present challenges that must be managed effectively. Common challenges include:

-

Soil and Groundwater Conditions: Designing to withstand specific site conditions like high water tables or unstable soil can be challenging. Solutions may involve specialized excavation techniques and dewatering systems.

-

Access and Space Constraints: In urban areas with limited space, using compact equipment and optimizing construction plans can help overcome access issues.

-

Structural Integrity and Durability: Ensuring the wall’s long-term strength requires high-quality materials and rigorous quality control measures.

-

Environmental Impact: Address environmental concerns such as noise and vibration by employing noise-reducing equipment and sustainable design practices.

-

Regulatory Compliance: Navigate complex regulations by engaging early with regulatory authorities and developing comprehensive compliance plans.

By anticipating these challenges and implementing effective solutions, construction professionals can successfully manage diaphragm wall projects and meet the expectations of clients and stakeholders.

Conclusion

Mastering diaphragm wall construction techniques in India is essential for successful civil engineering projects. Understanding the construction process and recognizing its benefits is crucial. By following best practices, engineers and contractors can effectively navigate challenges and achieve excellent results. As the construction industry evolves, staying updated on the latest advancements and maintaining expertise will be key to future success.