In the world of deep excavation and urban infrastructure, diaphragm wall construction (Dwall) stands out for its strength and stability. However, one crucial element that enhances the performance and safety of diaphragm walls – especially in high-retaining or waterlogged areas – is soil anchoring.

At Wagad Buildcon Pvt. Ltd., we integrate soil anchoring as a critical part of our Dwall projects to resist lateral earth pressure, reduce deformation, and improve structural reliability.

Here’s a detailed look at how the soil anchoring process works in Dwall construction.

🔩 What is Soil Anchoring in Dwall Construction?

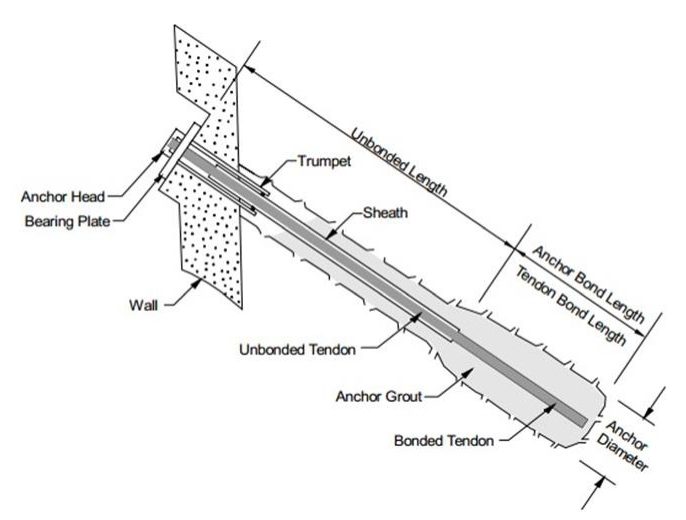

Soil anchoring involves the installation of prestressed steel anchors into the ground through the diaphragm wall. These anchors are grouted and tensioned to transfer load from the wall to the stable strata, ensuring minimal displacement and maximum stability during and after excavation.

🏗️ Key Stages of Soil Anchoring Process

1. Anchor Preparation

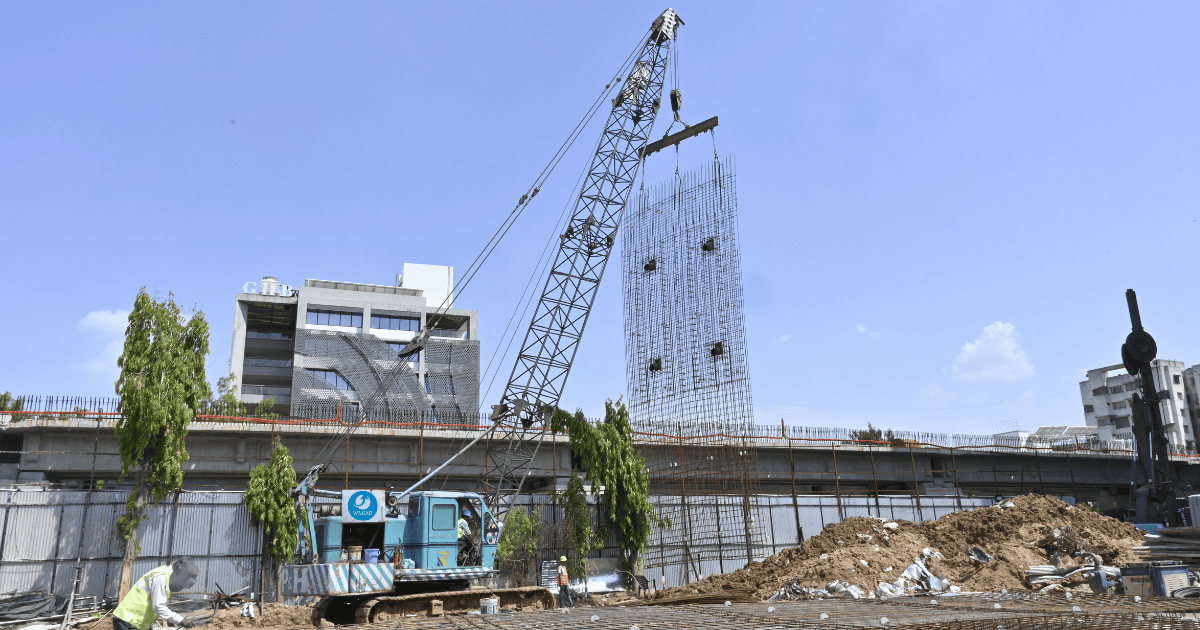

Before drilling begins, the required anchor layout, angle, depth, and capacity are finalized based on structural design. High-strength steel tendons or bars are prepared, often coated with anti-corrosive grease or sleeves to ensure long-term durability.

✅ Wagad Insight: Every site has unique geotechnical demands — and we tailor our anchor specifications accordingly.

2. Drilling & Anchor Insertion

Drilling is done at a specific inclination (usually 10–30° from horizontal) using rotary or percussion methods. Once the hole reaches the designed depth, the anchor system (tendon + sheath) is inserted into the borehole.

✔️ Inclined drilling helps anchor into stable soil/rock beyond the active pressure zone.

✔️ Anchor lengths often range from 8 to 25 meters, depending on depth and load requirements.

3. Grouting

Image Reference: www.researchgate.net

Grouting in soil anchoring is the process of injecting a grout mixture into a borehole to create a strong bond between the anchor and the surrounding soil or rock. This process is crucial for transferring tensile loads from the anchor to the ground, enhancing the stability of structures like retaining walls, bridge abutments, and excavations.

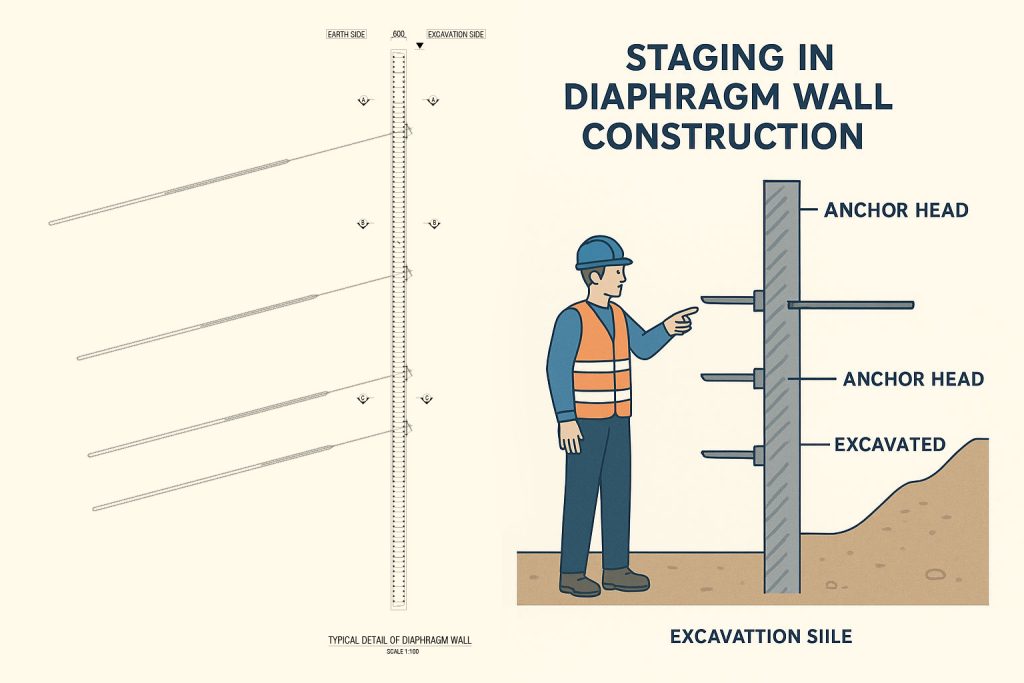

4. Anchor Head Fixing and Staging

Once the grout sets and gains sufficient strength, anchor heads are fixed onto the wall surface using bearing plates and wedges. These provide the interface for tensioning and structural engagement.

🧱 Staging: Anchor installation is done in stages as excavation progresses. This maintains equilibrium between wall pressure and excavation depth.

5. Tensioning and Lock-Off

Using hydraulic jacks, the anchor is tensioned to the required force and locked in place. This prestressing ensures that the wall remains stable, even before backfilling or structural support is complete.

⚠️ Safety Tip: All anchors are tested before lock-off to confirm load-carrying capacity and elongation behavior.

🌍 Why Soil Anchors Are Critical in Diaphragm Wall Projects

✔️ Enhance structural performance in deep excavations

✔️ Prevent wall deflection in soft or unstable soil zones

✔️ Reduce construction risks in high-density urban projects

✔️ Protect neighboring structures from vibration and settlement

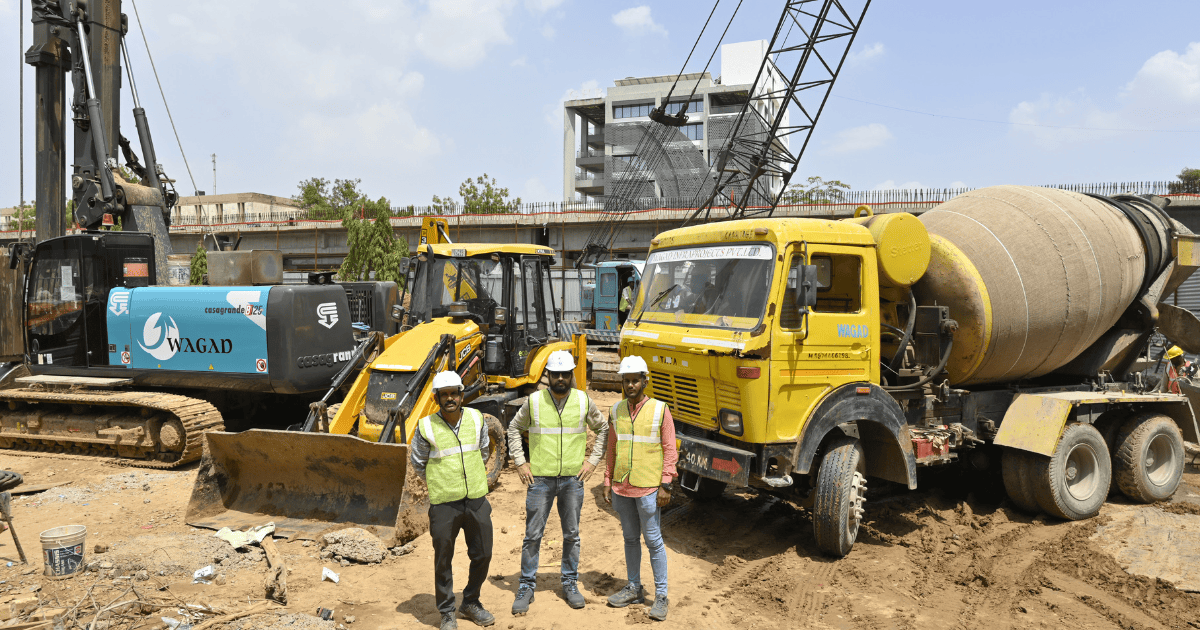

At Wagad Buildcon, we bring decades of field-tested knowledge to ensure every soil anchor is engineered, tested, and executed with precision.

🔧 Projects Where We’ve Applied This Expertise

Soil Anchoring in Dwall has become a vital solution in modern deep excavation projects, especially in congested urban zones where structural stability and safety are paramount. The integration of soil anchoring in diaphragm wall systems ensures that lateral earth pressure is effectively resisted, preventing wall deformation and minimizing risks to adjacent structures. Whether it’s for high-rise foundations, metros, or underground utilities, soil anchoring in Dwall provides unmatched load transfer efficiency and ground control. At Wagad Buildcon, we have mastered the process of soil anchoring in diaphragm wall construction by combining cutting-edge technology, precise grouting techniques, and stage-wise anchor tensioning, making us a trusted partner in India’s infrastructure growth.

From metro corridors and airport building basements to urban high-rise developments, our team has deployed thousands of meters of soil anchors to support diaphragm walls. Trusted by clients like Adani, Tata Projects, Smartworld Developers, DLF, Hero Homes, and more – Wagad Buildcon leads from the ground up.

✅ Conclusion: Deep Foundations Need Deep Expertise

Soil anchoring is more than a technical necessity — it’s a commitment to safety, performance, and longevity. When you partner with Wagad Buildcon Pvt. Ltd., you choose a team that understands the complexity beneath every structure.

Want to learn more or get a quote for diaphragm wall and anchoring services?

📩 Get in touch to dwall@wagadinfra.com or 📞 +91 89800 05155