Diaphragm wall construction has become a pivotal technique in the field of underground projects, particularly in urban settings like India, where space is at a premium. As cities grow vertically and the demand for underground infrastructure increases, this method offers unique advantages, making it increasingly popular in major urban centers, including Gurgaon, Noida, and Ahmedabad. This blog explores the top five benefits of diaphragm wall construction in underground projects, emphasizing its significance in Diaphragm wall construction in India

Enhanced Structural Stability

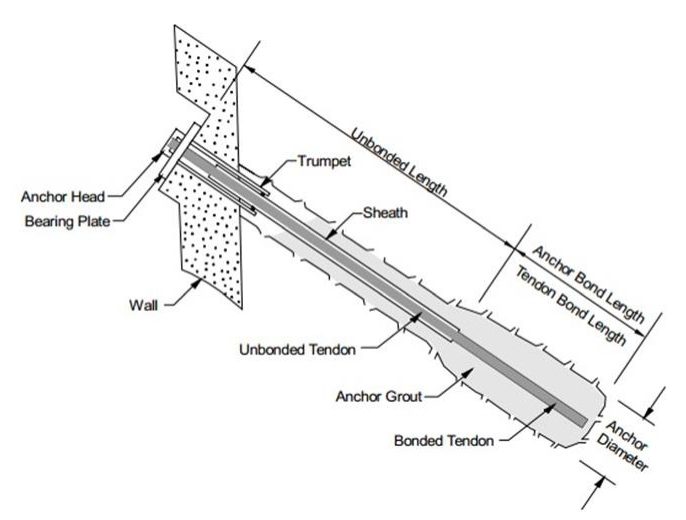

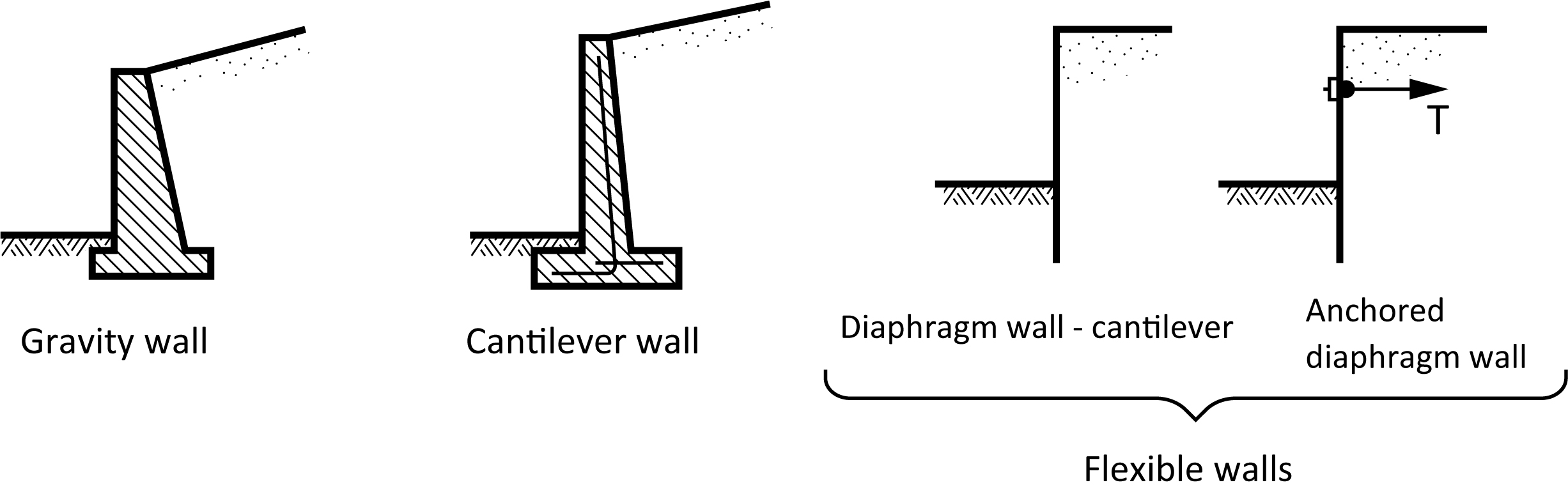

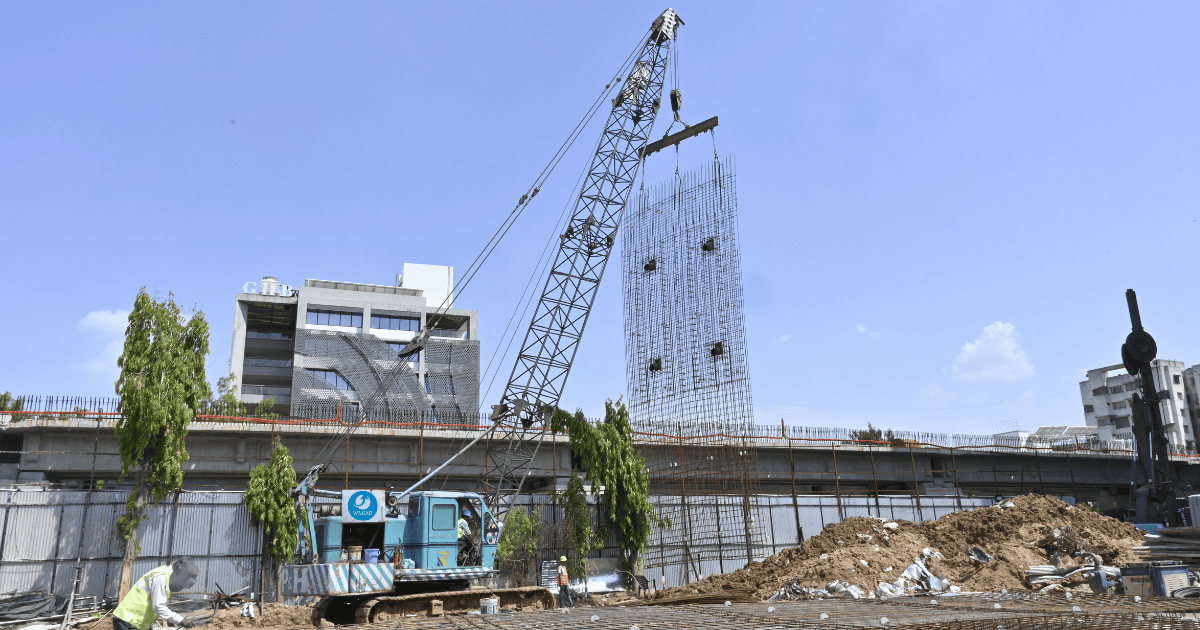

One of the foremost advantages of diaphragm wall construction is its ability to provide exceptional structural stability. These walls act as a rigid barrier, helping to retain soil and prevent water infiltration. This quality is crucial for underground projects, such as basements and tunnels, where maintaining the integrity of surrounding soil is essential. The robust nature of diaphragm walls makes them particularly suitable for areas prone to seismic activity, ensuring that structures remain secure even under duress.

In many Indian cities, where earthquakes can pose significant risks, the stability provided by diaphragm walls becomes a paramount concern. Their ability to withstand lateral pressures from the surrounding soil and water ensures that the structures built behind them are safe and long-lasting. Additionally, the design and construction of diaphragm walls allow for the integration of reinforcement, further enhancing their load-bearing capacity.

This structural integrity is critical not only for safety but also for maintaining the usability of the space above and around the construction site. As urban planners and architects strive to create sustainable, multi-functional spaces, the enhanced stability offered by diaphragm walls supports innovative designs that make the most of limited urban land.

Improved Water Management

Effective water management is a critical concern in any underground construction project. Diaphragm walls excel in this regard, functioning as impermeable barriers that prevent groundwater from entering the excavation site. This not only protects the structural integrity of the project but also minimizes the need for extensive dewatering systems. In cities like Noida and Ahmedabad, where groundwater levels can fluctuate significantly, the water-resistant properties of diaphragm walls make them an ideal choice for ensuring dry work conditions.

By controlling water ingress, diaphragm walls help mitigate the risks of waterlogging and soil erosion during and after construction. This advantage is especially relevant in regions that experience heavy rainfall or flooding, as it helps maintain a safe and dry environment for workers and machinery alike. Additionally, the reduced need for dewatering means that construction timelines can be adhered to more closely, avoiding delays and ensuring projects stay on schedule.

Moreover, with a growing emphasis on environmental conservation, the ability of diaphragm walls to manage groundwater effectively can contribute to sustainable urban development. By preventing groundwater depletion and maintaining natural water levels, diaphragm walls play a vital role in the preservation of local ecosystems, supporting biodiversity in urban landscapes.

Versatile Applications

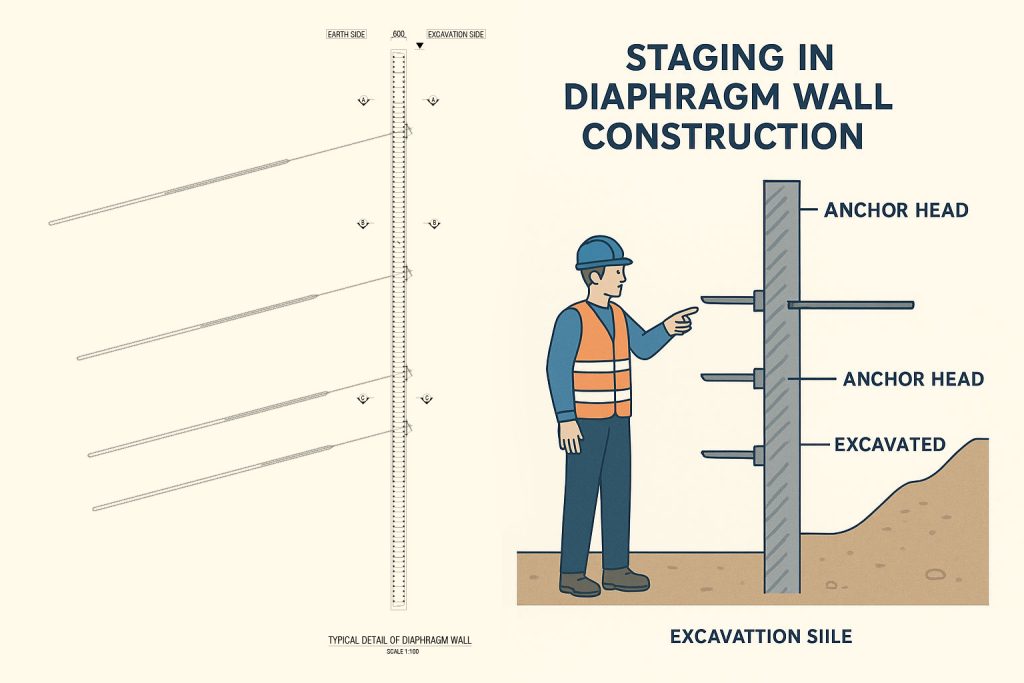

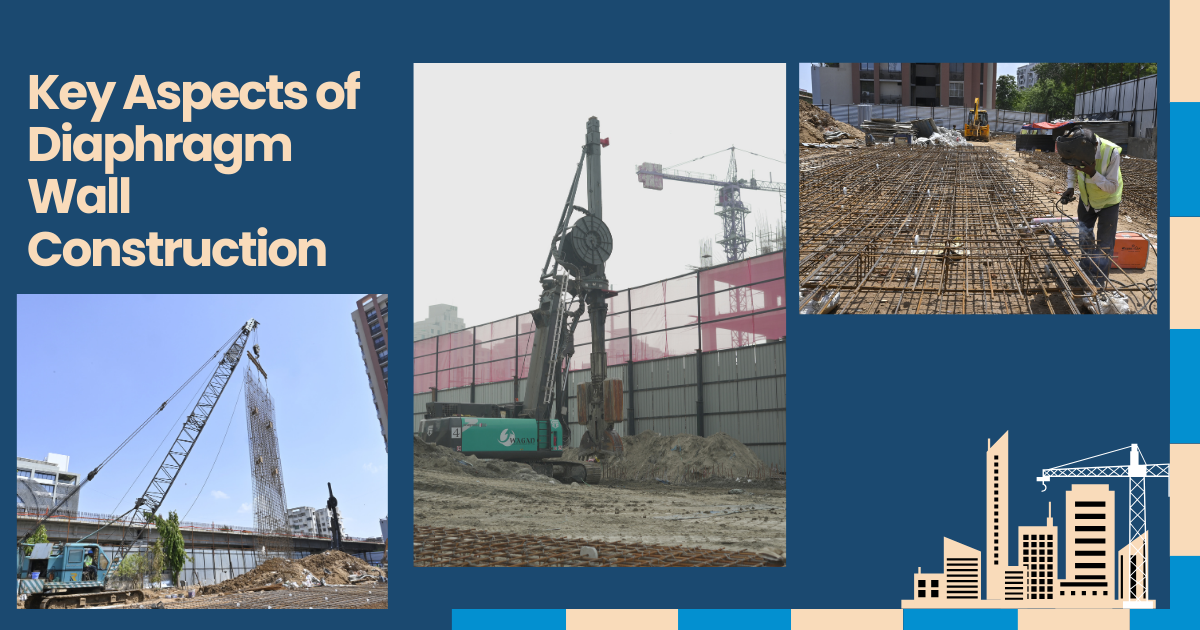

Diaphragm walls are incredibly versatile, making them suitable for a wide range of applications. Whether it’s constructing deep basements for commercial buildings, facilitating metro projects, or creating underground storage facilities, diaphragm walls can be tailored to meet specific project needs. Their adaptability allows for the accommodation of varying soil types and site conditions, ensuring that they can be effectively utilized across different geographical contexts in India.

The versatility of diaphragm walls is also evident in their use in complex urban environments. They can be designed to accommodate varying depths and thicknesses, allowing for flexibility in architectural and engineering designs. This makes them ideal for projects that require intricate layouts or special considerations, such as noise and vibration control in densely populated areas.

In addition, diaphragm walls can be combined with other construction techniques, further expanding their applicability. For instance, they can be integrated with ground improvement methods to enhance stability in challenging soil conditions or used alongside cut-and-cover tunneling techniques for underground transit systems. This multifaceted approach allows construction professionals to devise innovative solutions that meet the unique challenges of each project.

Reduced Environmental Impact

In an era where sustainability is paramount, diaphragm wall construction offers several environmental benefits. The technique typically involves less soil disturbance compared to traditional methods, leading to reduced excavation waste. Furthermore, by minimizing groundwater disruption, diaphragm walls help preserve local ecosystems. This is particularly important in urban settings where construction activities can have significant impacts on the surrounding environment.

By reducing the amount of soil that needs to be excavated and transported, diaphragm wall construction lessens the carbon footprint associated with construction activities. Additionally, the minimized disruption to groundwater flows helps maintain the ecological balance in urban areas, promoting the health of flora and fauna in surrounding regions.

Furthermore, diaphragm walls are often constructed using locally sourced materials, which can significantly reduce transportation emissions and support local economies. As sustainability becomes a key focus for urban development, the environmental advantages of diaphragm wall construction align closely with broader goals for responsible and eco-friendly building practices.

Cost-Effectiveness

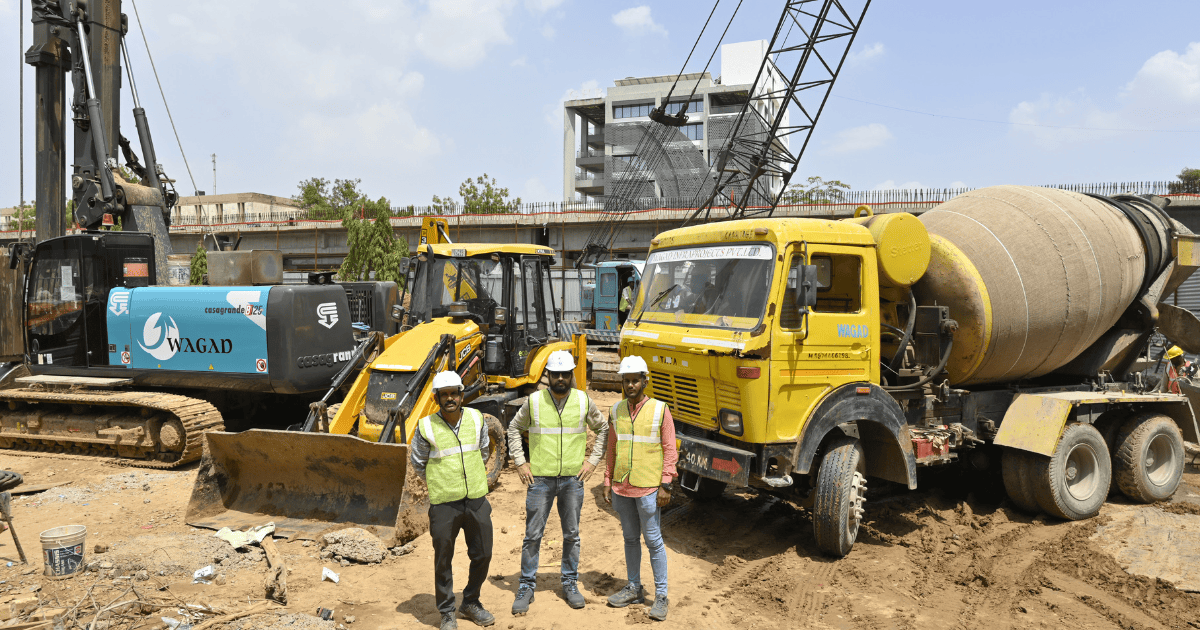

While the initial investment in diaphragm wall construction might seem higher than traditional methods, the long-term savings can be substantial. The durability and strength of diaphragm walls reduce the likelihood of future repairs and maintenance, resulting in lower lifecycle costs. Additionally, their efficiency in managing water reduces the expenses associated with dewatering systems.

For developers and contractors in India, particularly those offering diaphragm wall construction services, this cost-effectiveness can significantly enhance project viability. Over the course of a project’s life cycle, the financial benefits of reduced maintenance, improved safety, and minimized environmental impact often outweigh the upfront costs associated with diaphragm wall installation.

Moreover, the ability to accelerate construction timelines due to effective water management and reduced site disturbances translates into further financial savings. Projects that are completed on time can lead to quicker returns on investment, making diaphragm wall construction a smart choice for developers in competitive markets.

Conclusion

Diaphragm wall construction is revolutionizing underground projects across India, offering numerous benefits that address the challenges of modern construction. From enhanced structural stability and improved water management to versatile applications and reduced environmental impact, the advantages are compelling. As urban areas continue to grow, the adoption of diaphragm walls will likely become increasingly prevalent, solidifying their role as a cornerstone of safe and efficient underground construction.

For more information on diaphragm wall construction and to explore our services, visit Wagad Infra. Whether you’re looking for Diaphragm wall construction in Noida, Ahmedabad, or anywhere in India, we are here to meet your construction needs with expertise and reliability. With our commitment to quality and sustainability, we can help bring your underground construction projects to life, ensuring they are built to last.